|

|

Overview D-Bar, Select-Roller/A-Bar Characteristics Problems With Wire Bars For details, see our product lineup at www.j-osp.com/en/index.html |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: -Three-type three-layer smooth flow die (350 mm diameter) -high-efficiency DIREX extruder (75 mm ×1, 65 mm ×2) -Auto-gauge air ring (non-contact sensor type) -Internal cooling system (8 senor type) -Draw speed 120 m/min (max), speed ratio control -Draw Reversing Device (with program turnover function) -Chilled air generator -Carbon roll stabilizer -Carbon roll guide roll -Carbon roll bracer -Front and rear facing tension pick-up type rewinder -Selection of gap or contact rewinding -Max roll diameter: 1,000 mm Specifications: Max. Extrusion Volume: 650 kg/h Max. Productivity: 450 kg/h Variation Precision: 3-4% (actual results) Comments: As a fusion of our technology, this advanced, high-output film forming machine realizes the productivity of European built machines and the quality of Japanese built machines. |

|

Contact Information: |

Sales Office: Products: |

|

For users of conventional viscosity controllers who feel there are often glitches despite using these devices, who feel it is a pain to clean these devices, and who feel the precision and stability is poor, we can solve all of these problems by equipping our viscosity controllers with TURBO WASH and our SMART OIL INJECTION SYSTEM (patent pending). These overcome all of the common glitches, washing burden, and precision problems. |

|

Contact Information: |

Sales Office: Products: |

|

This water-based stripping/cleaning agent is ideal for washing anilox rollers, gravure cylinder, and inking rollers. One unique feature of the agent is that it physically strips the grime by penetrating the adhesion interface between the grime and the substrate instead of chemically dissolving or corroding the grime. |

|

Contact Information: |

Sales Office: Products: |

|

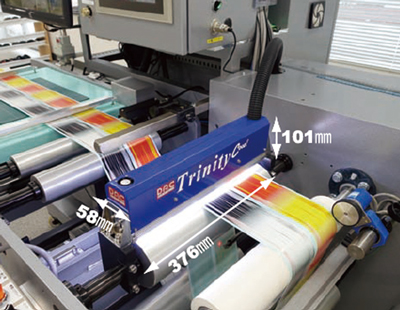

<Features> Integrated with a camera and LED lighting, the new Coco! optical sensor is designed to be compact. The sensor is able to produce uniform images with little distortion, clearly detects the edges of the image, and offers variable dpi resolution (150, 300, 600 dpi). The optical system in the Trinity Coco TCC301 Sticker & Label Inspection System is 58 × 101 × 376 mm in size and has an inspection width of 300 mm. The system photographs the surface of the labels in the rewinding machine or printing machine and converts the lines to an area density image. Meanwhile, full color image processing allows the system to automatically detect defects (contaminants, ink splatter, etc.). The system also displays rejected output and defect images in full color. In addition to local variable text inspection, the system is capable of inspecting the quality of the entire surface of every unit, even with digital printing where the printing data changes for each unit. <Specifications> ●Total Inspection Width 300 mm (with a 2,000 K Coco! sensor) <Application Examples> ● Double-sided business form printing inspection system |

|

Contact Information: |

Sales Office: Products: |