|

Characteristics: Specifications: |

|

“Thin” “Easy” “Compact” Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Since its inception in 1963, our coaters have been installed in many locations throughout the world in the paper and film industries, contributing to the development of new products and improvement of existing products. Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Specifications: Test Bar Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Through a technological exchange with a non-Japanese manufacturer in 1970, we developed this slitter/rewinder as a shift in thinking away from European concepts to Japanese needs under the strict quality management system of Japanese users. Our slitter/rewinders have been installed in many locations around the world. Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Through a technological exchange with a non-Japanese manufacturer in 1970, we developed this slitter/rewinder as a shift in thinking away from European concepts to Japanese needs under the strict quality management system of Japanese users. Our slitter/rewinders have been installed in many locations around the world. Specifications: |

|

Contact Information: |

Sales Office: Products: |

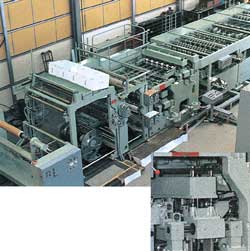

Characteristics:

1. Spiral Knife

-The relative angle of the upper and lower cutters is constant, producing a sharp, uniform cut face in the width direction

-High-speed is possible with low-capacity drive motor

-Realizes a significant reduction in cutting noise

2. Cutter Function Design for Long-term, Consistent Operation

-Backlash is maintenance free over the long term using a unique shim calibration system

-The cutter drum realizes both low-inertia and high-durability

3. Automated Product Stacking/Labor Saving

-Automated skid setting

-Automated positioning of side guide and front stop

-High-speed transport and stacking

Basic Specifications:

Applicable Substrates: high tensile strength steel plates, tin plated steel plates, aluminum, stainless steel

Applicable Substrate Thickness: 0.1 to 0.6 mm

Applicable Substrate Width: 1,250 mm (max.)

Cutting Length: 460 mm (min.)

Cutting Speed: 240 m/min (max.)

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: |

|

Contact Information: |

Sales Office: Products: |

|

Low-cost!! |

|

Characteristics: Specifications: Options: |

|

Contact Information: |

Sales Office: Products: |