|

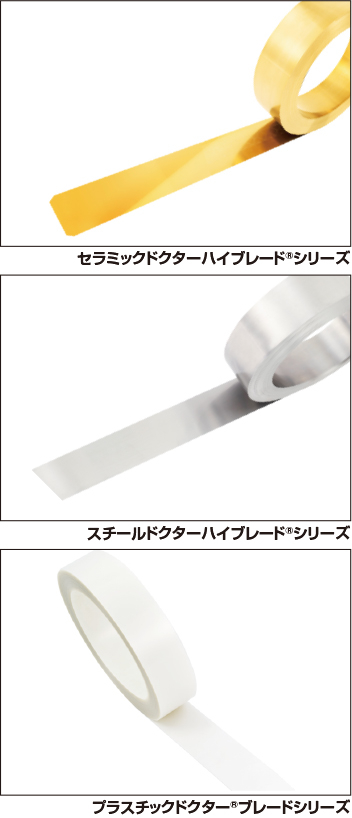

【Steel Doctor Hi-Blade® Series】

Produced under the strictest quality management conditions for everything from materials to grinding and inspection, our many years of experience and know-how are brought together in our Steel Doctor Hi-Blade Series.

Doctor Hi-Blade®

Produced by our craftsmen using our in-house developed precision grinders, the Doctor Hi-Blade is our standard model and has been lovingly used for many years by our customers. The blade edge is uniquely ground based on our many years of experience and know-how.

Gold Doctor Hi-Blade

This model is produced with the latest high-grade steel, which contains greater amounts of wear-resistant components than standard Swedish steel. The durability is extremely high, and the blade hugs the plate uniformly across the width.

Doctor Hi-Blade R-ST

Our highest grade model, the edge of this blade is formed using a special grinding process unique to our company. The blade is extremely effective in eliminating streaks found in half tone sections.

Stainless Steel Doctor/Stainless Steel Doctor XP

Using a special alloy of Swedish stainless steel, the blade has high durability and corrosion resistance. It is also suited to severe printing conditions where water and acid are used.

Benton Doctor

This blade is given an edge using a unique grinding method not found at other companies. Typically, a whetstone is used to grind the blade edge, but Benton Graphics Inc. uses a chemical treatment (corrosion method) to form the edge. As such, the ground area is extremely smooth, and there is only a minimal amount of variation and roughness.

Back-Up Doctor Blade

This is an important item that allows our Doctor Hi-Blades to be used more effectively. The Back-Up Doctor Blade can be applied to various doctor sizes, so please choose the size that suits your needs.

Doctor Hi-Blade® Precision Blade

The edge of this blade precisely ground, which minimizes grinding variation and ensures the blade edge chips uniformly during use. The edge is angled where the blade contacts the cylinder. The blade is processed so that it begins to function well immediately and so that the doctor cutting performance is improved. The blade is most effective for high-precision printing, including coating.

Doctor Hi-Blade® Flexotip

Developed as a specialized blade for flexo printing, the blade is ground through a completely unique method unlike that used for conventional blades. In doing so, we improved the doctor cutting precision and the durability.

【Ceramic Doctor Hi-Blade® Series】

By applying a surface treatment to our Steel Doctor Hi-Blades, we developed a high-grade doctor with improved wear resistance and wiping capability. As a pioneer of long ceramic doctors, this product is packed with our years of history and credibility.

K Ceramic Doctor HQ Series

This blade was developed to reduce the printing defects, such as streaks, feathering, and catching, often encountered by our customers. As a doctor blade manufacturer, we conducted research and collected data over many years, eventually developing a doctor blade that is able to effectively mitigate such printing defects.

This series is made of the highest-grade Swedish steel hand-picked by our staff and the edge is ground using our unique high-precision grinding process. We also improved the areas of ceramic surface coating to strengthen the adhesion between the steel and ceramic coating.

The synergistic effect of our unique high-precision grinding process and improved coating allows the blade edge to rapidly conform to the cylinder surface, improves the doctor cut, and ensures the edge chips finely and uniformly. The fine chipping of the edge increases the useable life of the blade.

K Ceramic Doctor

This is our most highly recommended doctor blade, developed through a fusion of our unique grinding and surface treatment technologies. Compared with our conventional blades, the coating adhesion and wear resistance are greatly improved. Our many years of know-how are found through this model.

Roots Doctor

By adopting a component with good lubrication for the surface coating, this model ensures good sliding and doctor cutting. It is particularly suited for use with water-based inks. We also offer a special white color type.

Soft Doctor Hi-Blade

This model has a thinner surface coating for a lower hardness that is still able to provide wear resistance. This blade is able to reduce damage to the plate.

Pure Alloy Doctor Blade

This model is made with a special nickel alloy coating. The surface hardness is low but offers high corrosion resistance.

【Plastic Docto®r Blade Series】

We have continued to develop soft doctor blades suited to all types of printing and coating. We offer select items that have been tested repeatedly in terms of material strength, adhesion, thickness, hardness, geometry, and cost.

PET-S, PET-D Series

Hi-PET Series

Hi-PE Series

Hi-POM Series

|