|

The GLS-2060 inline non-contact gloss meter measures the surface gloss of continuously produced printed products, plastic films, stone material, tile, and coatings, for example, in realtime without contacting the subject while displaying time series data. The gloss meter allows for rapid observation of the production line condition. Further, all of the measured data collected by the gloss meter are saved, so detailed evaluations can be made at a later time.

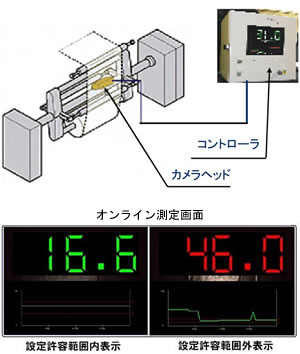

-Newly Developed Camera Head

This camera head suited to inline installation uses an ultra-high intensity LED light source.

-Stable Gloss Measurement

A proprietary measurement algorithm allows the gloss meter to make stable gloss measurements

-Simultaneous Display of Gloss Value and Time Series Data

Digitally displays realtime gloss values and a time series graph on a monitor.

-Interval Control of Gloss Value Acquisition and Saving

*Timing control for the specialized controller allows for fixed intermittent data and total data to be saved.

*The specialized controller can acquire gloss data from fixed intervals synchronized with the encoder pulse (option).

-Gloss Value Correction

The gloss value correction function allows the operator to set a correction value for each measuring environment.

-Two camera heads can be connected

-A still image system can also be connected using one PC/controller (option).

-Low-cost

The industry’s first inline non-contact measurement method allows the gloss meter to achieve excellent cost performance.

Measurement Principle:

An ultra-bright LED light source is used to project light at an angle of 60º, which is reflected and captured by the CCD camera set at a incident light angle of 60º. The amount of captured light, the gloss level, is then calculate by a proprietary RGB brightness histogram method. The size of the received light measurement image can be set by the user via software control.

When the measured gloss value falls within the reference tolerance, it is displayed as “green,” and when it falls outside this range, it is displayed as “red.” This approach simplifies abnormality management during processing. Further, all of the data acquired by the gloss meter can be saved.

When outside the reference tolerance range, along with displaying the value in red, the system can send an output signal that can be used to activate a buzzer or warning light.

|