|

Characteristics: New Product: Applications: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Applications: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Primary Specifications: Products: |

|

Contact Information: |

Sales Office: Products: |

|

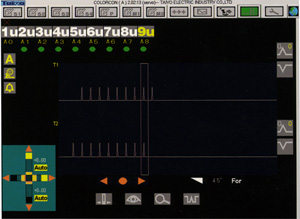

Colorcon is an automated registration system for multi-color gravure printing. The DT-3000 is an improved version of our well-received DT-950M II and DT-2000 systems. The DT-3000 is designed for compensatorless registration control of AC servo motor control, sectional drive gravure printing machines. Characteristics: |

|

Contact Information: |

Sales Office: Products: |

|

-“Technology and Reliability” is Sumitomo Heavy Industries Modern’s extrusion laminator Characteristics: |

|

Contact Information: |

Sales Office: Products: |

|

ロール傷問題を完全解決したスコアーカット用アンビルロールです。 <特徴> <仕様> <特徴> <仕様> |

Sales Office: Products: |