|

Characteristics: Applications: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

|

Contact Information: |

Sales Office: Products: |

|

|

Contact Information: |

Sales Office: Products: |

|

Our highly awaited off-line, all-purpose automated paper polishing system is now available -Handles face lengths of 200 to 1,300 mm and diameters of 100 to 300 mm |

|

Contact Information: |

Sales Office: Products: |

|

This new machine, which is able to use microbeads of 0.05-1.0 mm in diameter, is aimed at research and development using samples as small as 100 cc. The agitator uses an accelerator that effectively and uniformly transfers energy to the beads. One feature of this machine is the integrated feed screw, which supplies the material to be dispersed and allows for pumpless self-circulation operations. Moreover, the grinding chamber has a structure that allows it to be easily removed from the motor drive, allowing for easy bead filling, disassembling for cleaning, and reassembly. -Cylinder Volume: 80 cc |

|

Contact Information: |

Sales Office: Products: |

|

Using a newly developed centrifuge separator, this new machine allows for the use of microbeads of 0.03 to 0.2 mm in diameter. The centrifuge separator has an independent drive, for which the revolutions can be set independently from the agitator speed to achieve a stable flow for materials ranging from low to high viscosity. In addition, the agitator uses the same accelerator as the ECM type, so allows for efficient, uniform energy transfer to the beads. Nanomaterial dispersion does not require a strong impact force; rather, applying a strong impact force to the primary particles would cause problems with co-agglomeration because the surface energy of the particles increases when they are destroyed. By using microbeads, it is possible to effectively disperse the nanomaterials without having to grind the raw material particles. |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: |

|

Contact Information: |

Sales Office: Products: |

|

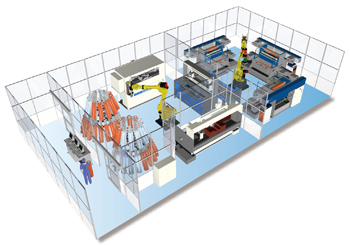

<Features> <Specifications> Turret type (LM-SF1300T), Dry/non-solvent dual purpose type (LM-Combi-800S) are available. |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Specifications: |

|

Contact Information: |

Sales Office: Products: |