|

|

Contact Information: |

Sales Office: Products: |

|

|

Contact Information: |

Sales Office: Products: |

|

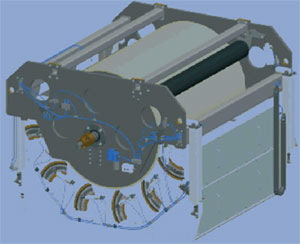

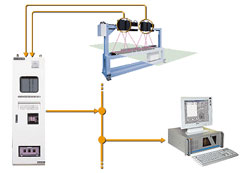

[ Feature ] [ Adaptation material ] [ Specification ] |

|

Contact Information: |

Sales Office: Products: |

|

[Feature] [Applicatioon] [Specifications] Rings used for individual frictional winding shaft can be sold separately. |

|

Contact Information: |

Sales Office: Products: |

|

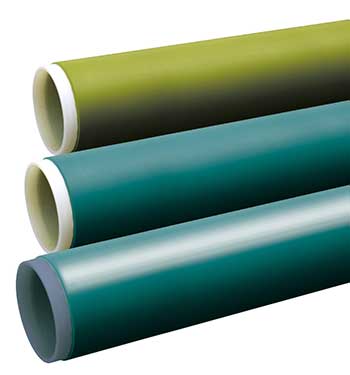

“e-core K” “e-core R” “e-core RT” |

|

Contact Information: |

Sales Office: Products: |