|

A “sealed” coating system that reduces solvent vaporization between the supply system and coating head is an essential criterion for consistently delivering high-quality coating. HIRANO TECSEED offers multiple “Die Coating Methods” adjusted to various coating film thicknesses, resin properties, and substrate characteristics to do just this. Of these, the “DV Coater” is especially suited to ultra-thin-film coating. Characteristics: Specifications/Applications: |

|

Contact Information: |

Sales Office: Products: |

|

Since its development, we have sold more than 500 our lip coaters, which have been well received on the global market. In lip coating, the resin weight calculated based on the numerically input coating conditions is fed to the lip head. These conditions are controlled by the lip coater specialized L301 controller, which can be used to remotely adjust the lip head coating gap using a key control. The lip head has a mechanism that allows the lip to be bent on the left and right sides, as well as the middle, which allows for free width direction resin profile control. Applications: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

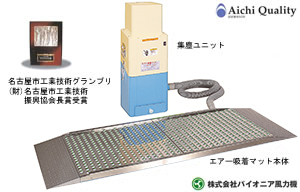

Our air suction mat is a high-performance, energy saving entryway mat that can be used simply by placing it at a building entrance or passageway to remove particles attached to the soles of shoes or vehicle tires via a spring brush and air suction. High-performance |

|

Contact Information: |

Sales Office: Products: |

|

Tension Controller C500 controls tension during running of materials processed in sheet form, including paper, fabric, fibers, film, rubber, and metal. Characteristics |

|

Contact Information: |

Sales Office: Products: |

|

The Tension Meter T300 displays the tension during running of materials processed in sheet form, including paper, cloth, fibers, film, rubber, and metal. At the same time, the T300 provides output for recording meters, external meters, and sequencers, etc. Characteristics |

|

Contact Information: |

Sales Office: Products: |

|

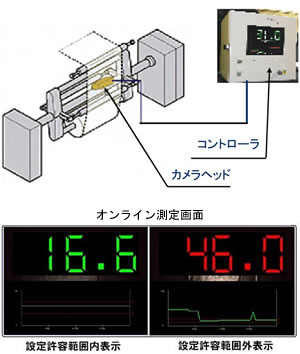

The GLS-2060 inline non-contact gloss meter measures the surface gloss of continuously produced printed products, plastic films, stone material, tile, and coatings, for example, in realtime without contacting the subject while displaying time series data. The gloss meter allows for rapid observation of the production line condition. Further, all of the measured data collected by the gloss meter are saved, so detailed evaluations can be made at a later time. -Newly Developed Camera Head Measurement Principle: When the measured gloss value falls within the reference tolerance, it is displayed as “green,” and when it falls outside this range, it is displayed as “red.” This approach simplifies abnormality management during processing. Further, all of the data acquired by the gloss meter can be saved. When outside the reference tolerance range, along with displaying the value in red, the system can send an output signal that can be used to activate a buzzer or warning light. |

|

Contact Information: |

Sales Office: Products: |

|

Handles water-based ink at a maximum machine speed of 250 m/min. The machine concept is “High-speed” and “High-environmental Performance.” This high-end model focuses on system operability, controllability, and reduced loss. Characteristics: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Basic Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Basic Specifications: Characteristics: |

|

Contact Information: |

Sales Office: Products: |